Product Description:

Polypropylene Fiber (PP Fiber) is made from 100% virgin PP granular, after extruding from different mould and technology, we can get 4 different types of fiber, including Monofilament form, Fibrillated Mesh form, Twisted Bunchy and Wave form with different size. These fiber can improve the reinforcement of mortar or concrete performance effectively to make them strong and protect the projects.

Feature & Function:

1. Easy to be dispersed in mortar or concrete and no agglomeration, it can guarantee the property of crack resistance effectively.

2. Easy to be used: No need to change the proportion of mortar, just put the fibers into the mortar mixture and stir for a moment after adding water.

3. It with fine economic property: The equivalent diameter of PP Fiber monofilament is only φ 0.02-0.03mm, so the ratio of diameter and surface area is high and on the basis of crack resistance, it can reduce the amount (to about 0.6-0.9kg/m 3 ).

4. Easy to plaster: As the great number of thin fibers spread into mortar evenly, the plastering is much easily and this can improve the binding strength between surface and base.

5. It with stable chemical property, strong acid &alkali resistance, and can be used in any engineering projects.

| Resist to shrink & crack | Increase seepage resistance |

| Increase friction resistance | Increase freezing & thawing resistance |

| Improve tendons protection | Replace steel net (using in plastering) |

| Prevent mortar split and crackle expansion | Increase impact resistance and peeling resistance |

Suitable Project

1). Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance. The life span of these projects will be lengthened for 5-10 years.

2). The walls of tunnels, mines, roofs and reservoir projects with special construction. When using spray technology in concrete construction, the PP fiber added into the concrete can effectively decrease the spray concrete's deformation rate of the walls less than 8% and that of the roof less than 12%, and also can reduce the friction. It can improve the constructing efficiency and working environment and popularize the spray technology.

3). River courses and dams, etc. The PP fiber can improve concrete's resistance to crack and squirt and wear to lengthen projects' life span.

4). Military defense works, dock banks and piers, etc. This fiber can greatly strengthen the concrete's spurt resistance and heighten these projects' safety and lengthen their life span.

2. Ratio Design: Usually the proper amount of fiber to concrete is 0.9kg/m3 , and the water-proof layer of the bridge requires 1.35-1.8kg/m3, and the spray concrete in the tunnel is also the same and other materials remain the same. The ratio of fiber and concrete can be determined by tests for special purposes. The fiber has better effects on the concrete with active compound materials, such as silicon ash, coal powder, ground slag and zeolite powder.

3. Mixer Adoption: Double-axle horizontal compelling mixer is better and self-dropping cylinder mixer can be used, too.

4. Mixing Process: Crushed stones, fibers and sands are put into the mixer in succession. After stirring for two minutes, fiber will fully spread and then add cement and water and stir normally. The addition of materials also can be put into as usual, but the stirring time should be properly prolonged to make fiber completely mixed.

5. Stirring Time: The purpose of the stirring is to make fiber fully spread into monofilament or the net fully spread, so generally the stirring time is 2-3minutes after the addition of polypropylene fiber-mesh.

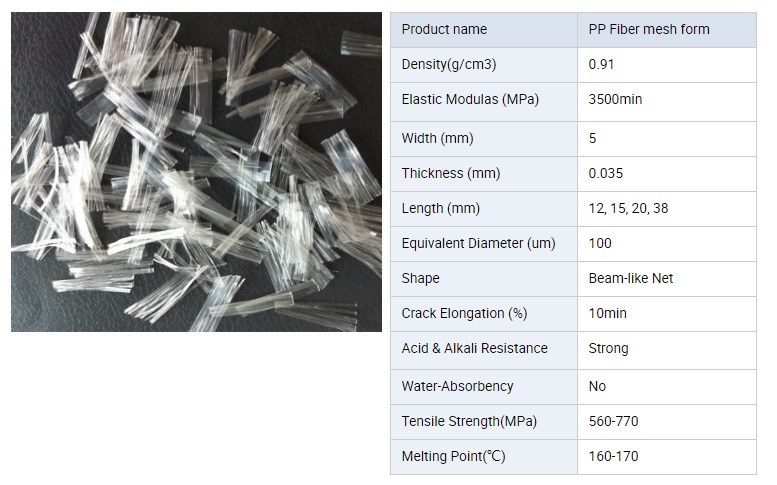

Specification:

Material--------------------------Polypropylene

Density(g/cm3) ---------------- 0.91

Elastic Modulas (MPa)--------3500min.

Width (mm)----------------------5

Thickness (mm)----------------0.035

Length(mm) --------------------12, 15, 20, 38

Equivalent Diameter (um) ----100

Shape ----------------------------Beam-like Net

Crack Elongation(%)-----------10min.

Acid &Alkali Resistance ------Strong

Water-Absorbency -------------No

Tensile Strength(MPa)---------560-770

Melting Point(ºC) -------------160-170

Packing one:

1).: 600g, 900g, 1kg net per PE bag

2).: about 20kgs per plastic woven bag

3).: 6500kgs/1X20`FCL without pallet

Packing two:

1).: 600g, 900g or 1kg net per water soluble paper bag.

2).: 20kgs per carton

3).: 5200kgs/1X20`FCL without pallet

2-3weeks after all thing be confirmed.

Contact information:

Emma Wang

Tel: +86-551-63522028

Mobile: 86-18855132322